Drinking water and groundwater protection

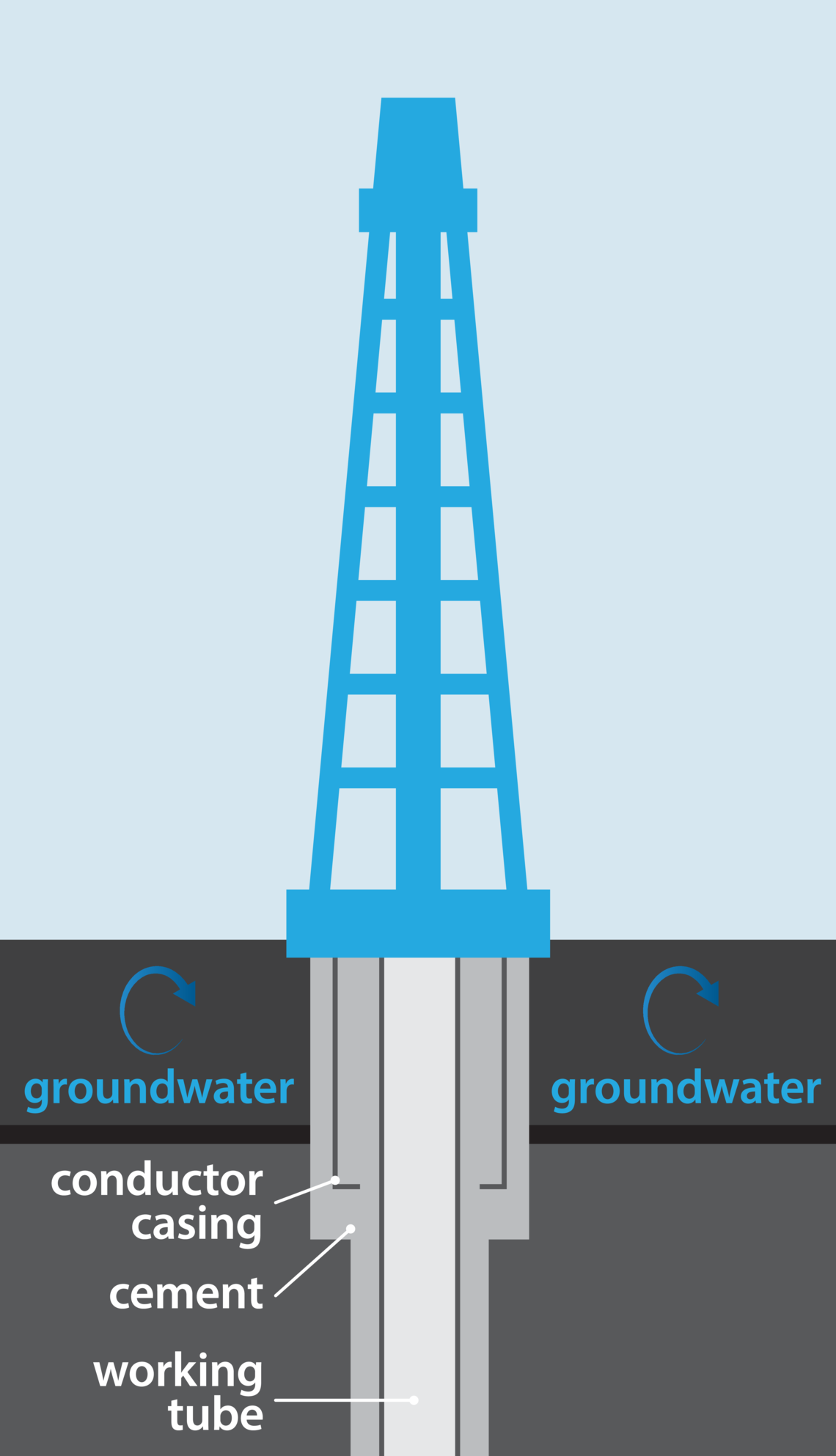

At least two boreholes, the production well and the injection well, are required to access the hot deep water at depths of several kilometers. During their construction, various aquifers, some of which are used for drinking water supplies, must be drilled through. To protect this valuable resource in the best possible way, higher water legislation provides certain regulations, that compliance with which is permanently monitored.

To ensure the best possible protection, so-called conductor casings are installed as part of the drilling pad construction. These casings are made of steel and are driven into the ground below the groundwater horizon in a similar way to sheet piling. They form a tight barrier between the drilling work and the surrounding near-surface layers. The first pipe section, several hundred meters long, is then cemented into the conductor casing, forming a triple-protected area (steel - cement - steel). This ensures that the hot deep water is always routed within a closed system. We only use its heat, not the water itself as in thermal bath.

A large and heavy drilling rig is used to drill the boreholes. As with any machine, there are mechanically moving parts that need to be lubricated. In order to protect the subsoil and drinking water from lubricants washed off by rain, the inner area of the drill pad, where the rig is located, is asphalted and designed so that liquids drain inwards into the so-called “drill cellar”.

This area is regularly drained by specialized companies. In the outer area of the drill pad, where trucks maneuver and office containers are parked, rainwater is drained into the sewer system.